Thus, the scope of the machine control is taken into account. Examples of 2D parts might be gears or signs. 2D CAM programs are focused on creating tool paths for flat items without any surface curves. 3D printers Workcell simulation software, 3D modeling, CAD/CAM. CAD/CAM programs come in two variants, 2D and 3D. In this case, for example, all those areas of the geometry are interpolated, that is, decomposed into sequences of straight lines and circular arcs that are not easily transferred to the machine control (spline curves, spline surfaces) - in such a way that, if possible, tangential transitions are created. We offer an Associates Degree in Mechatronics and several different certificates.

With our NC processors, on the other hand, only the toolpaths that you generated in advance using CAM strategies are generated as NC code.

#Cad cam cnc 3d degrees code

However, this does not guarantee that the NC code sent to the machine will correspond exactly to your requirements. The difference is as simple as it is serious: Traditionally, a postprocessor converts generated CAM strategies into another format. The focus is on importing an existing 3D model (STL files) and providing basic manipulation capability, like rotation, scaling, etc. A 3D only CAD/CAM program for generating CNC code from existing models. The many automatic functions, integrated. Incidentally, our NC processors are not post-processors. CNC machine code generation for 3D models. FASTTRIM is fully integrated in the powerful CATIA V5 CAD/CAM infrastructure. Introduction to Computer Aided Design and Manufacturing (CAD/CAM). The erosion process is then displayed even more transparently. Attitude and quality of workmanship is stressed.

#Cad cam cnc 3d degrees software

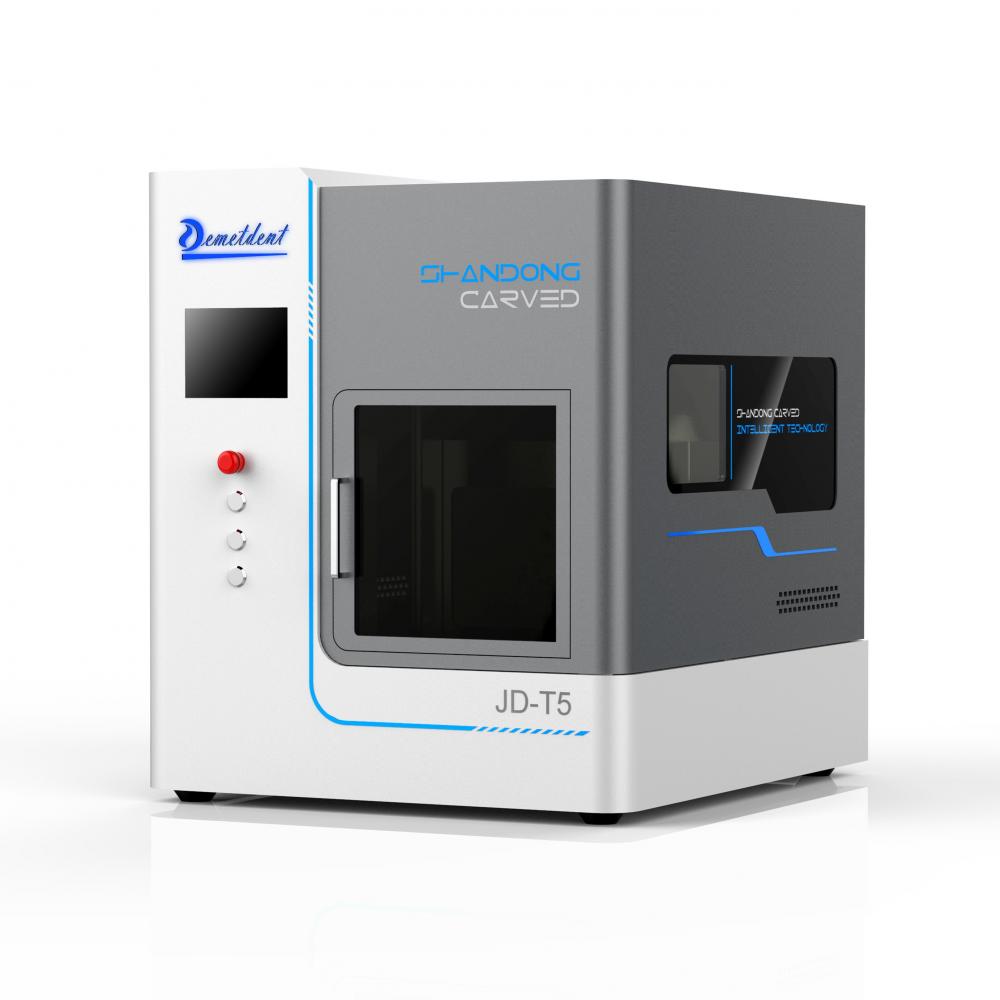

Also, we shall discuss the 10 best free CAD/CAM software programs and their features. Let us dive deep into the world of CAD CAM and figure out how it works. Now, for the fun part: creating 3D textures and. CAD CAM software programs are being widely used across next-level designing, prototyping, and manufacturing industries, from dentistry to aerospace. Rather than a square and blocky shape for the vise, I used 3D drawing tools in Rhino3D to give it a gently curved shape.

#Cad cam cnc 3d degrees registration

This course is designed to meet competency-based standards set by the industry. In earlier posts, I used CAD software to create the 2D design for the BARN Workbench vise chop and the I built a pin registration board for two-sided machining on my CNC. This tool can also be used together with the 3D simulation. Students will work in the areas of blueprint reading, computer numerical control (CNC) machining, general machining and maintenance, computer-aided drafting (CAD) and related mathematics. This allows you to check at any time during programming whether it meets your expectations.Īdditional security is provided by the NC browser: After programming, you can localize and again check any contour area, NC code-based. The unique NC processor technology from DCAMCUT offers you maximum control over your programming steps, as the software generates the associated NC code in the background.

0 kommentar(er)

0 kommentar(er)